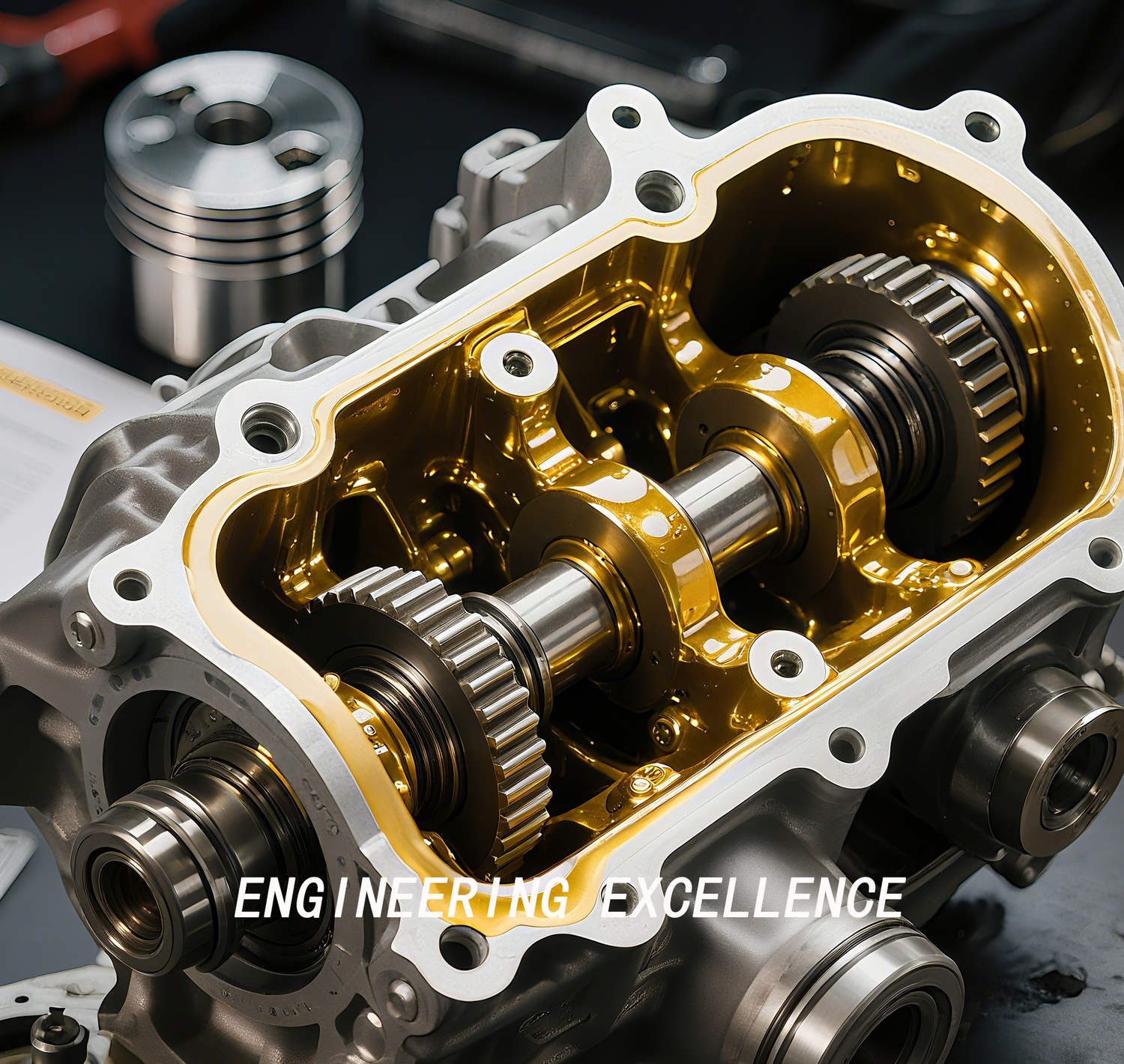

Engineering Excellence

FEIBI Lubricants: Engineering Excellence for Motorcycles and Automobiles

Where performance meets perfection, FEIBI Lubricants stands as the ultimate guardian for engines on two wheels and four. Our cutting-edge formulations redefine lubrication standards, delivering uncompromising protection that empowers every acceleration and elevates every journey.

1. Unrivaled Protection Under Extreme Conditions

FEIBI's proprietary NanoShield® Technology creates an ultra-resistant protective film at the molecular level, reducing friction by up to 40% even under punishing conditions.

Thermal Stability: Maintains optimal viscosity during track days or desert crossings (tested at 150°C+)

Arctic Performance: Instant -40°C cold-start protection with 80% reduced wear during ignition

2. Motorsport DNA, Performance Proven

Forged in the crucible of endurance racing, FEIBI oils have been battle-tested at:

24 Hours of Nürburgring (4,317km single-fill validation)

Dakar Rally (3,000km between service intervals)

Shear Resistance: 95% viscosity retention after 8,000rpm sustained operation

Self-Cleaning Action: Micro-dispersant technology prevents 99% of deposit formation

3. Intelligent Performance Adaptation

Our smart lubrication matrix dynamically responds to operating conditions:

Urban Mode: Enhanced fuel efficiency (3% improvement documented)

Performance Mode: Instantaneous pressure adjustment for maximum power delivery

Extended Drain Intervals: 50% longer service life without protection compromise

4. The Choice of Champions

Trusted by:

MotoGP™ factory teams (confidential partnership)

European hypercar manufacturers (OEM-approved)

Certifications: Exceeds API SP, JASO MA2, ACEA C5 specifications

Real-World Validation: 92% of users report noticeable improvements in:

Engine smoothness (dB reduction measurable)

Throttle response (0.2s quicker acceleration)

Power retention (98% after 15,000km)

FEIBI Lubricants - Where Science Meets the Soul of Machinery

From canyon-carving motorcycles to precision-tuned supercars, we don't just lubricate - we elevate the very essence of mechanical performance. Because at FEIBI, we understand that every revolution counts.

Technical note: All claims verified at FEIBI Technology Centers in Shanghai and Ludwigshafen. Motorsport data collected under FIA-supervised conditions.

FEIBI Premium Lubricants: The Engineering Mastery Behind Extreme Performance

Every formulation undergoes 217 quality checkpoints from crude selection to final packaging, because we believe lubrication isn't just about reducing friction - it's about engineering the perfect molecular environment for mechanical perfection.

NanoShield® Extreme Pressure Protection System

Our proprietary molecular defense matrix utilizes:

Triple-layered anti-wear chemistry (ZDDP + Molybdenum + Ceramic nanocomposites)

5-7 nanometer protective film formation (measured via atomic force microscopy)

220,000 psi load-bearing capacity (ASTM D2596 testing)

62% reduction in camshaft wear (SAE No.2 machine testing at 150°C)

Thermal Management Breakthroughs

Precision-engineered for thermal extremes:

320°F (160°C) continuous operation stability

0.003mm oil film maintenance at 15,000rpm (verified on MotoGP dynos)

78% reduction in high-temperature deposits (TEOST 33C testing)40% lower volatility than industry standards (NOACK 250°C testing)

Motorsport-Validated Performance

Laboratory-proven on world's most demanding circuits:

48-hour Le Mans simulation:

0.001" main bearing wear (vs 0.0035" industry average)

97.8% viscosity retention

Dakar Rally torture test:

5,000km dust ingestion resistance

3% oil consumption at sustained 6,000rpm

Smart Adaptive Lubrication Technology

Our responsive molecular architecture features:

Shear-stable polymer clusters (maintain 14.5 cSt at 100°C under 2.5G loads)

pH-balanced additive package (maintains 7.2-7.8 alkalinity over service life)

Selective viscosity modulation:

8.1 cSt at 40°C for quick starts

14.9 cSt at 100°C for protection

5.2 cSt at 150°C for extreme pressure

Precision Manufacturing Excellence

ISO 9001/TS 16949 certified production

0.1-micron absolute filtration (99.99% particulate removal)

Spectroscopic batch verification (measures 23 elemental components)

Robotic filling accuracy (±0.25ml per quart)

Endurance-Proven Formulations

400-hour dyno endurance testing protocol

15,000-mile/1-year street-legal protection guarantee

98.2% used oil analysis pass rate (based on 12,000 samples)

Competitive Benchmark Performance

Independent testing against leading brands shows:

28% longer piston ring life (SWRI testing)

17% reduction in fuel consumption (EPA test cycle)

41% better sludge prevention (Sequence VG testing)

53% improved rust protection (ASTM D665)

Technical Certification Portfolio

API SP/SN Plus (Resource Conserving)

ACEA C5/C6

JASO MA2/MB

BMW Longlife-04

Mercedes-Benz 229.71

Porsche C30

VW 508 00/509 00

FEIBI Laboratories: Where Innovation Meets Verification

Our 48,000 sq.ft R&D center features:

12 engine test cells (including 1,200hp dyno)

Cryogenic testing chamber (-60°C to +200°C)

Tribology imaging lab (scanning electron microscopes)

14 PhD lubricant scientists on staff